Autori: S. M. Iftiquar, Youngwoo Lee, Minkyu Ju, Nagarajan Balaji, Suresh Kumar Dhungel si Junsin Yi

Titlul original: Fabrication of Crystalline Silicon Solar Cell with Emitter Diffusion, SiNx Surface Passivation and Screen Printing of Electrode

College of Information and Communication Engineering, Sungkyunkwan University, Republic of Korea & Department of Energy Science, Sungkyunkwan University, Republic of Korea

An aparitie: 2012

Ce este celula solara?

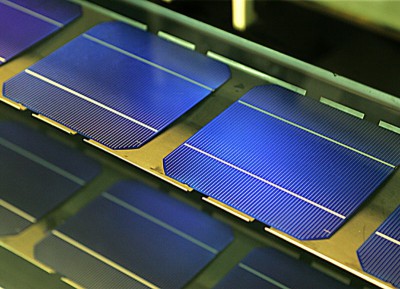

Celula solara consta din doua sau mai multe straturi de material semiconductor, cel mai intalnit fiind siliciul. Aceste straturi au o grosime cuprinsa intre 0.001 si 0.2 mm si sunt dopate cu anumite elemente chimice pentru a forma jonctiuni „p” si „n”.

Functionarea celulei solare (fotovoltaice)

Aceasta structura e similara cu a unei diode. Cand stratul de siliciu este expus la lumina se va produce o „agitatie” a electronilor din material si va fi generat un curent electric.

Celulele, numite si celule fotovoltaice, au de obicei o suprafata foarte mica si curentul generat de o singura celula este mic dar combinatii serie, paralel ale acestor celule pot produce curenti suficient de mari pentru a putea fi utilizati in practica. Pentru aceasta, celulele sunt incapsulate in panouri care le ofera rezistenta mecanica si la intemperii.

Structura cursului

1. Introduction

2. Fabrication Process for Industrially Applicable Crystalline Silicon Solar Cells

2.1. Wafer Cleaning and Saw Damage Removal

2.2. Surface Texturing

2.3. Phosphorus Diffusion for p-n Junction Formation

2.4. Edge Isolation by Wet Chemical Etching

2.5. Antireflection Coating and Front Surface Passivation

2.6. Metallization

2.6.2. Co-firing of Screen Printed Pastes

2.6.3. Study of rear surface passivation with SiNx film

3. Measurement Results for c-Si Solar Cells

3.1. Wafer Cleaning and Saw Damage Removal

3.2. Surface Texturing

3.3. Phosphorus Diffusion for p-n Junction Formation

3.4. Antireflection Coating and Front Surface Passivation

3.4.1. Carrier lifetime measurement

3.4.2. Effect of different passivating layer on carrier lifetime

3.5. Metallization

3.5.1. Effect of Co-firing Temperature on Solar Cell Performance

3.5.2. Study of rear surface passivation with SiNx film

4. Summary and Future Direction for Thin Silicon Wafer Processing

4.1. Summary

4.2. Future Direction for Thin Silicon Wafer Processing

Pentru o intelegere mai clara materialului de fata, intregul proces de fabricatie a celulelor cristaline este prezentat in materialul video de mai jos:

Bibliografie:

Tensiunea foarte mica e problema pentru care trebuie legate in serie, celulele individuale de 0,5V, acest fapt generand problema compromiterii unui intreg panou la defectarea unei singure celule.